I’ve always wanted a pianola/player piano, but have never been able to afford one. Conlon Nancarrow was the original and most famous composer who used a player piano to compose works which were impossible for humans to play – too many notes, too widely spread across the keyboard, and too fast.

I wasn’t quite thinking of emulating that, but I thought it would be interesting to compose by making holes in a strip of card, which is what you have to do with the types of musical boxes which are available.

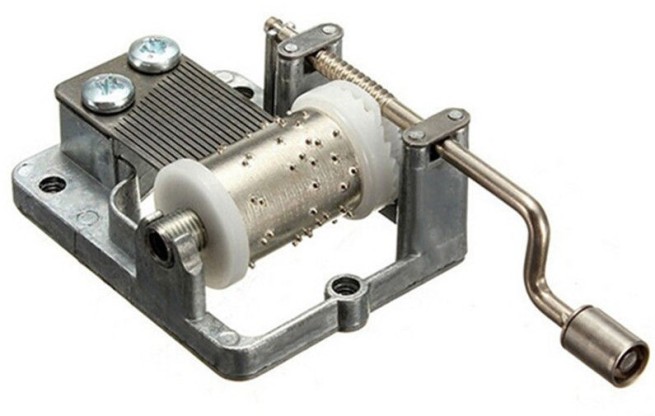

A quick look at eBay shows there are several variations. Aside from this type, which plays a fixed tune, either manual:

or wind-up:

there are several types which are, as it were, ‘programmable’, meaning you can create your own tunes to play on them. The usual ones are 15-note (top of the picture) or 30 note (bottom of the picture):

The 30 note type shows how the thin card strip feeds through the mechanism. The top roller is the guide and the bottom roller with the ‘spikes’ is the one that plays the notes.

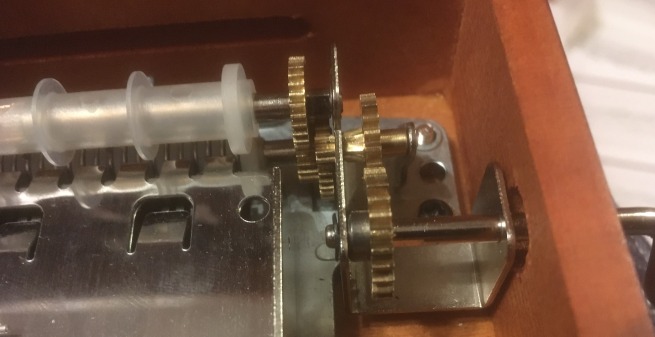

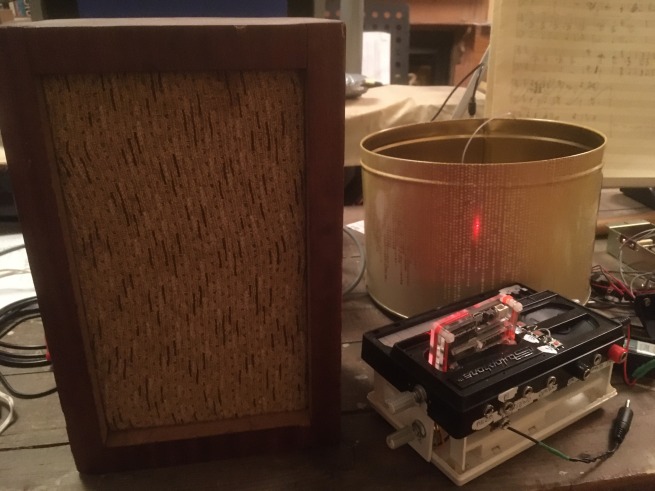

I was rather attracted by a 30 note type which was already installed inside an attractive wooden box:

You can see the slot on the front of the box where the card is fed into the mechanism. It emerges through a similar slot on the other side. The mechanism itself can be accessed by opening the lid of the box:

It was rather more expensive than the mechanism just by itself, but I thought, well, it looks so much nicer, and the box will act as a sounding board, to improve the sound of the instrument as it plays.

The cost for this one was £29.99, including postage from China, but you can get the mechanism without the box for £22. They usually come with a few card strips and a special hole-punch, but you’ll need extra strips, which cost around £5 for 10 strips of 75cm – there’s a limit to how fast you can wind the musical box, so I’d estimate you wouldn’t get much more than 30 seconds of music from a strip of that length.

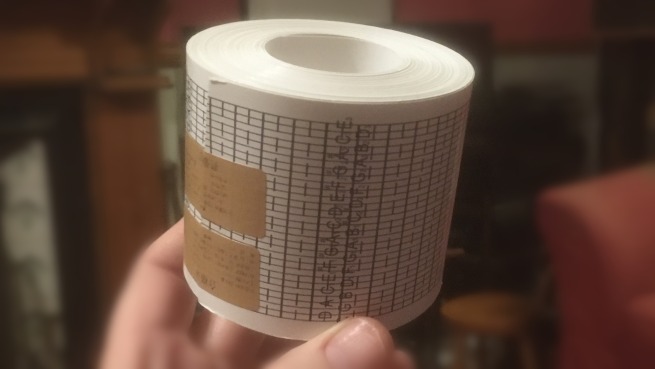

This is what the strips look like:

but to save you having to join strips together – although this isn’t difficult, as I describe below – you can also get a continuous 10m strip like this:

*

The king of the musical box is undoubtedly Martin Molin of the Swedish group Wintergatan. Perhaps better known as the inventor of the wonderful Marble Machine, Martin has also posted a number of videos on YouTube about his work with a 30-note musical box, including details of its construction and making the punched-hole card strips which play the tunes. Here’s an example which begins with a great view of the musical box live on stage.

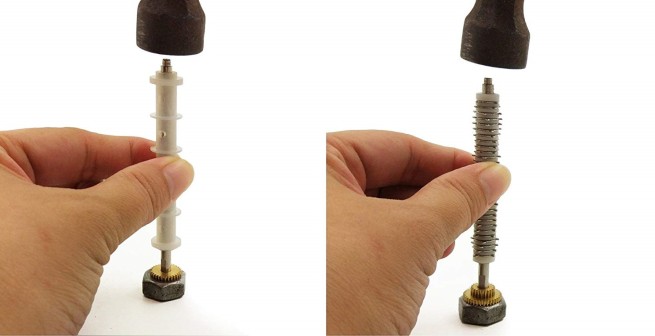

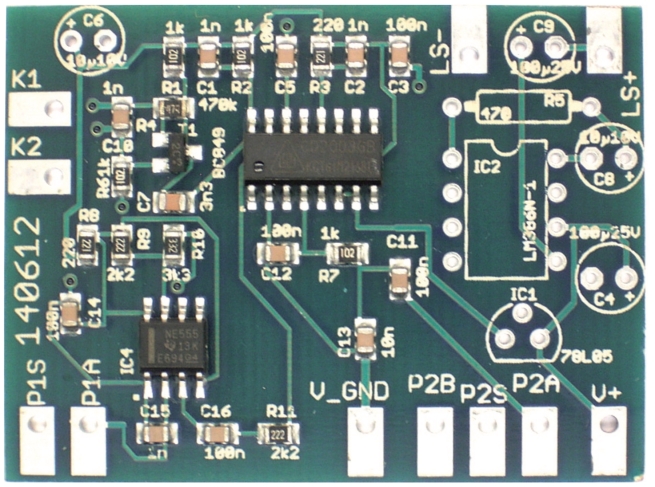

I watched all the videos carefully, and was concerned by Martin’s comments on the problems he had with reliability, which he put down to the plastic cogs in the mechanism. You can see those in the picture above.

As a result of that, I decided to bite the bullet and buy a set of metal replacement cogs. These came from the UK, but were still £13.33 including postage, so this was becoming rather an expensive project. However, the one 30-note mechanism I saw which already had metal cogs was £55, so I suppose buying my own had saved a bit of money . . .

The advert said they were made of copper, although they were surely brass, which would be the normal materal for such things. When they arrived, they were clearly precisely the correct set for this mechanism, matching the dimensions of the plastic ones exactly, and even included replacement screws and washers, which wouldn’t be needed if the originals were retained during dismantling.

The instructions for replacement were included in the eBay listing, a series of very clear pictorial illustrations of the procedure. I was a bit concerned before I started, as I wasn’t sure if it would be as easy as it looked in the pictures – but it was!

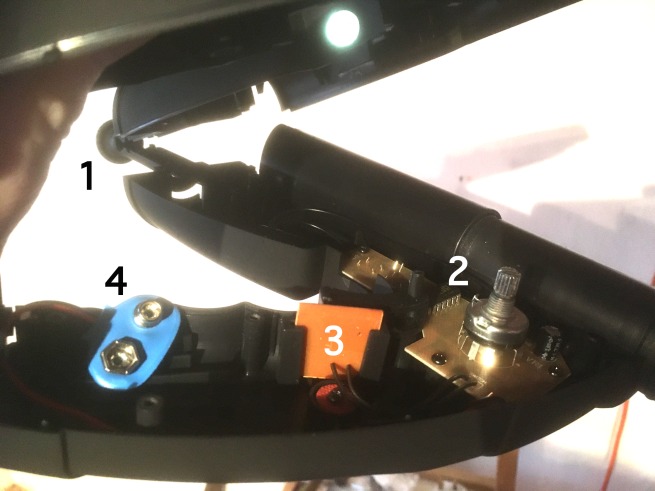

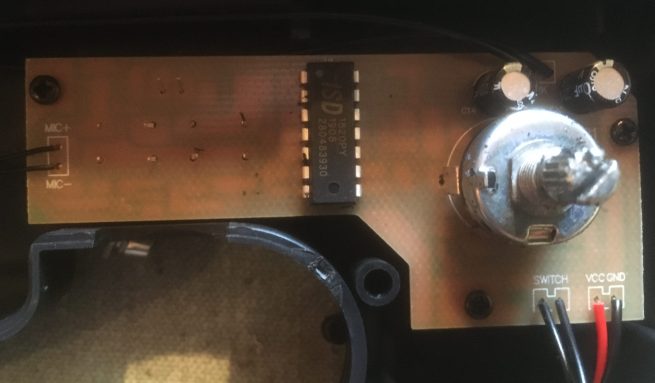

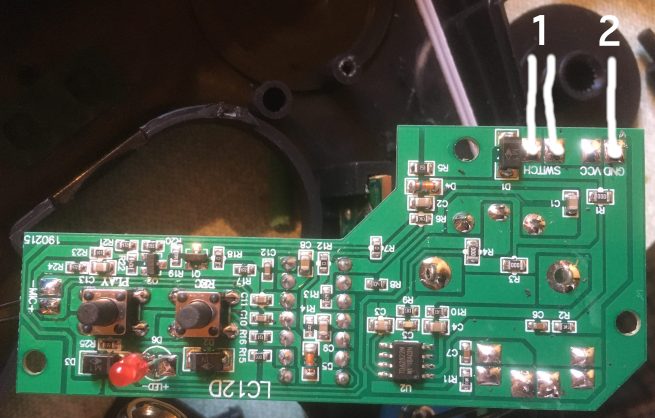

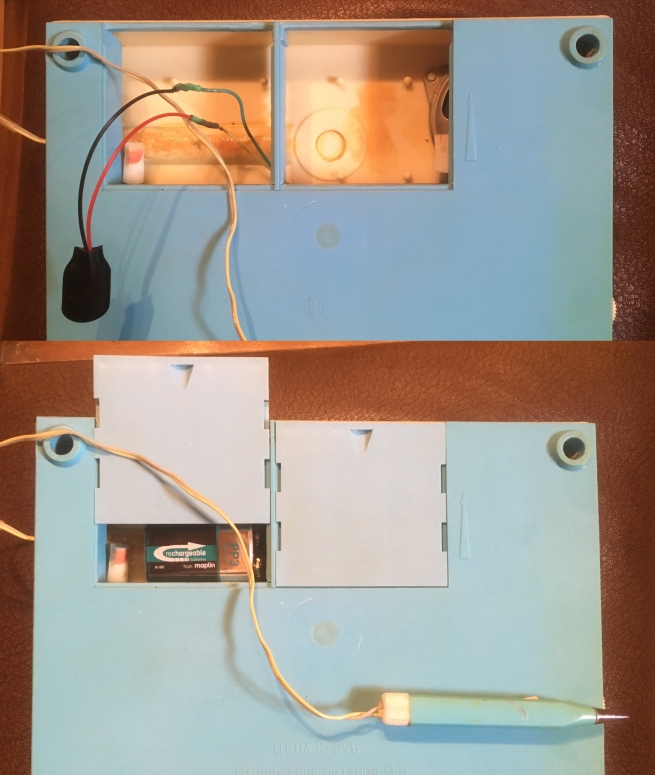

The mechanism was attached to the box by 4 screws on the underside.

To take it out, these 4 screws needed removing, plus two screws on the inside, which attached the handle to the main part of the mechanism.

Removal of the plastic cogs was easy, requiring a little work with fine-nosed pliars – I also need them to pull off the ones which are shown here being removed by hand: they were on a little too tightly to do that.

Likewise, putting the new cogs in. In a couple of cases, this was just a matter of putting them in place, bending the retaining arm back into position in one case, and replacing a small clip in another.

Even the ones on the rollers, which had to be gently hammered into position, were easily done in exactly the way shown in the instructions. Resting the assembly on a nut, it was possible to move the new cog slowly into place by tapping on the top.

I gave the new cogs a light spray with WD40 before reassembling the mechanism in the box.

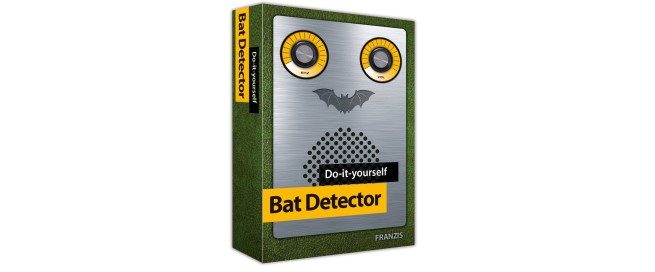

[Edit: following a comment made below, I bought some proper clock oil to use instead of WD40 – a wonderful cleaner, but not a proper lubricant, and can attract water, dust and dirt. There are many different types available, but one I bought was this one:

The cost was only £3.50, and regular use will keep the new cogs turning smoothly.]

Everything fitted precisely, and the only give in the system turned out to be the base of the box, which was loose and moved slightly while the mechanism was being wound. This was soon cured with a couple of spots of superglue.

I tried the new arrangement out, and it worked perfectly. With luck, this should now be sufficiently robust for me not to have to worry about slipping or jamming when I’m trying to play music.

*

Next, then, I needed to work on some punched-hole strips to play some music. It seemed to me that there were 3 things I could do: firstly, transcribe some music I had already written; secondly, write some new pieces especially for the musical box; and thirdly, create some music unique to the instrument by punching random holes, or holes in patterns where part of the pleasure would come from not knowing what it would sound like until fed into the machine!

*

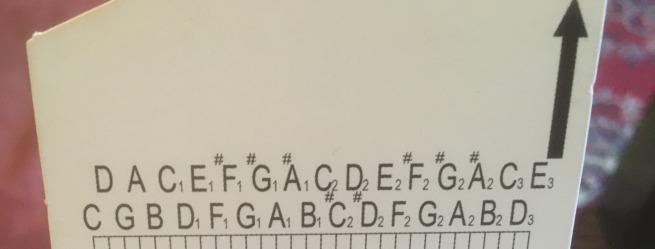

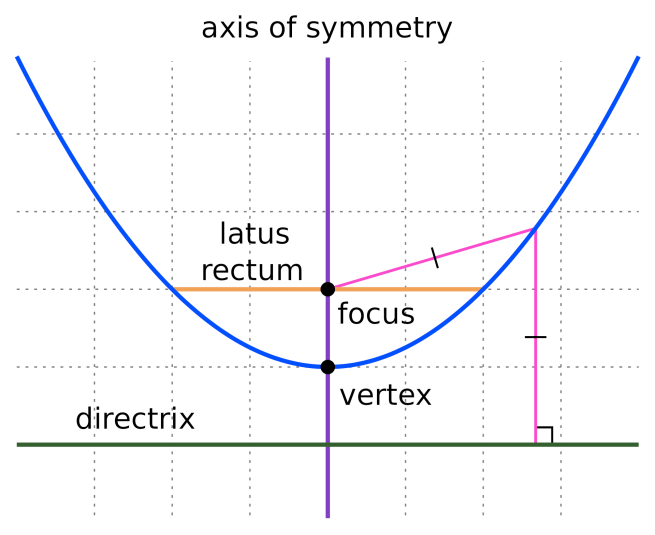

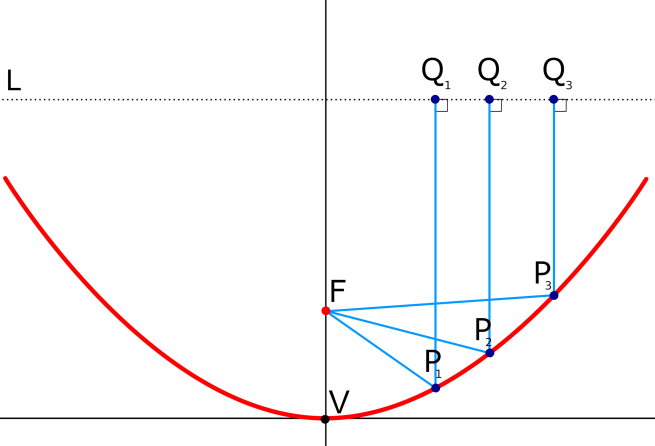

The beginning of the strip was printed with the 30 notes, and a helpful indication of which direction the strip should travel:

The first thing which is apparent is that the 30 notes are not a continuous two and a half octave scale. Looking carefully, you can see nearly two octaves of continuous notes from E1 to C3; below E1 there are 7 ‘bass’ notes, extending just over an octave below; above C3 there are just 2 higher notes; so there is a range of just over 3 octaves, but with some notes missing – principally sharps or flats – meaning that some keys will more easily able to use the full range of notes than others.

The format of the card strip is simple enough: each of the 30 notes is represented by one of the 30 lines that runs the length of the strip. Make a hole at a certain point on that line and the corresponding note will sound.

A special hole-punch which was suitable for this job was included with the kit:

There are lots of nice punches out there that can make 2mm holes, like these:

but they’re all useless, as the card strips are 70mm (7cm/2¾”) wide, so the punch needs jaws of at least 35mm depth, and preferably more: the hole-punching part of the exercise is very tedious, and the deeper the jaws of the punch, the easier this job is going to be. The supplied punch allows you to reach about 50mm across the strip, which is most of the way, if not all the way, and was, in fact, far enough for most of what I did, without having to turn the strip around and finish off punching from the other side.

*

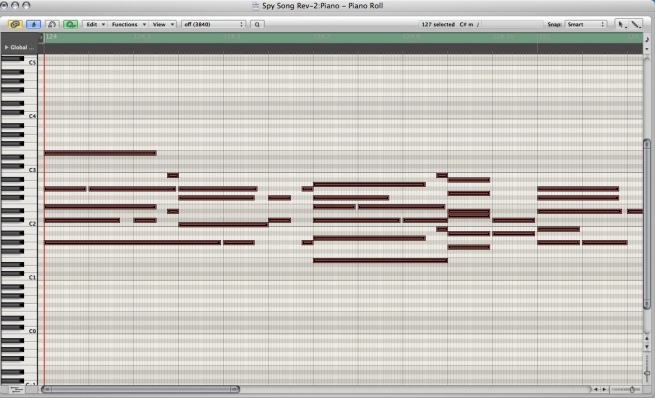

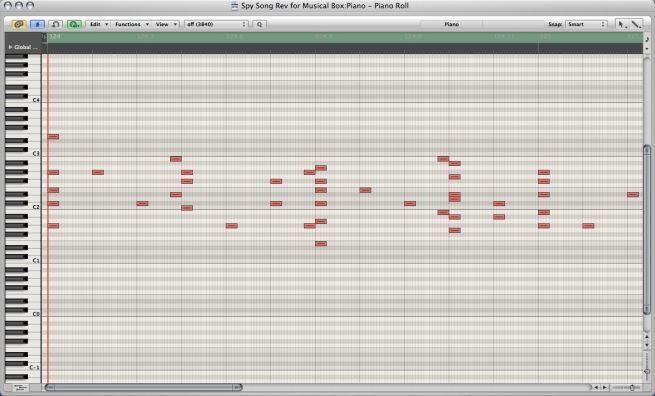

To start with the transcription of pieces I had already written, I turned to the application Logic, where they had for the most part been written. One of the views you can have of a piece in Logic is called the ‘piano roll’. This looks exactly like the strip above, with the lowest note at the bottom, the highest note at the top, and a dot (for a short note) or a line (for a long note) in exactly the place where it needs to sound.

I found some suitable pieces which were written wholly or mainly for a single instrument and turned to the piano roll view. Typically, it might look like this screenshot, with short notes represented by a short line, longer notes represented by a longer line; the piano keyboard on the left-hand side indicated which note was which:

There were two things I had to do with this representation of the piece for it to be of use to me in preparing the card strips.

First of all, I had to remove or reposition notes so there were none outside the range of the musical box – the piece above, while perfectly OK on the piano, has notes which are both too high and too low for the musical box.

This is an example of a section where all the notes have been adjusted to fall within the musical box’s range:

Secondly, as the musical box doesn’t distinguish between short notes and long notes, I needed to reduce the length of the lines so they were all very short, like the holes that I would be making in the strips.

This is what the piece looked like when I had done that:

In this way I had reasonably quickly come up with a template which I could copy onto a strip, and hopefully reproduce – albeit slightly simplified – a piece I had already written.

I printed out the screenshots:

and started copying the dots in the screenshots onto the card strip.

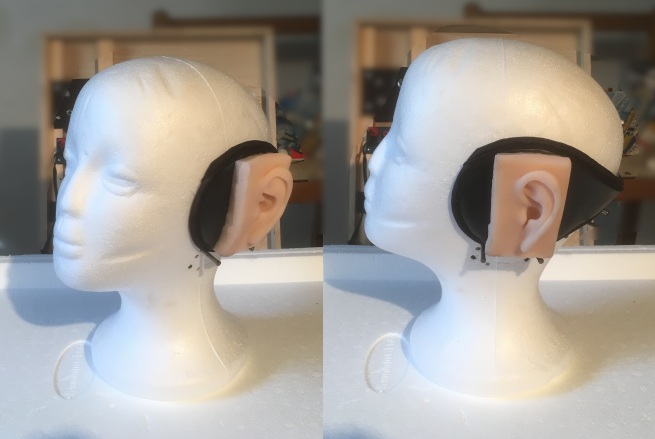

Soon after I started marking dots on the card strip, I found this to be a useful tool (the one on the right if you’re left-handed):

This is the guide to the notes cut off the left-hand end of a strip; the one on the right is from the right-hand end.

The problem is that while you’re near the beginning of the strip, it’s easy to see which line corresponds to which note; but the further away you get from the end, the harder it is to see which note is which. The first piece I finished used several strips joined together, and was about 2 metres long. It would be pretty well impossible to keep looking back to the end to work out where to place a mark or punch a hole, so using this indicator in one hand, while I marked the dots with the other was very helpful for making sure I chose the right note.

The further I got from the left-hand end, the more useful this tool became; and eventually, as I implied above, I had to extend the strip by joining another one onto it.

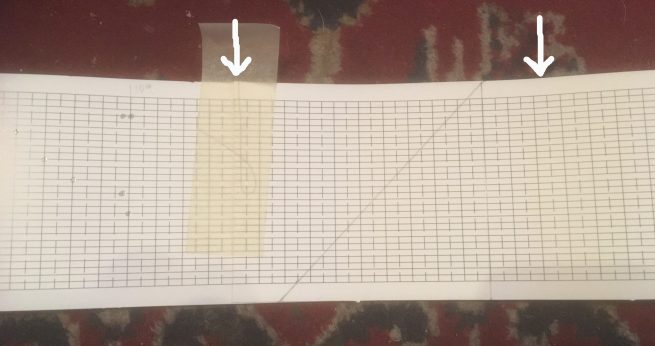

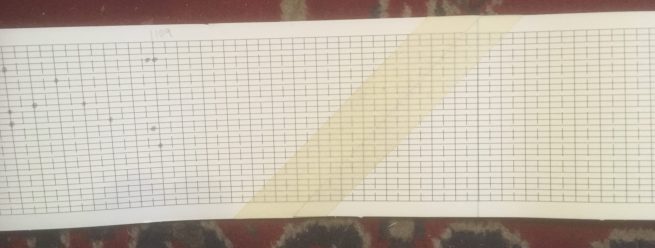

I decided the best way to do this was somewhat like splicing audio or video tape, which we don’t do now, but used to have to do years ago. So, my recommended method is to cut off the end of the new strip – the part with the notes on it can be put aside for a new tool when marking dots in future, and the remaining part trimmed along a easily identifiable line:

This strip can then be stuck over the strip you’re coming to the end of. The edge should be matched precisely with the existing strip, and the two strips should overlap so that a diagonal line can be drawn at about 45° across the part where the two strips overlap.

The picture shows the strips temporarily stuck together with masking tape. I used masking tape for this job because it’s not too sticky – especially for this first join, which is temporary; it’s see-through, so it won’t stop you adding new dots when you continue work later; and it’s quite thin, so it won’t cause the strip to get jammed in the musical box mechanism. The arrows indicate the area where the two strips overlap, and the diagonal line is shown in between them.

To finish off, cut along the diagonal line with craft knife or scissors, undo the temporary join and fix the two strips together, end-to-end, with no overlap. I only used masking tape on one side for this as putting tape on both sides of made the card rather thick and it wasn’t going through the musical box mechanism very easily.

I decided to stop after every page of screenshots, having marked in the dots, and punch the holes, so I didn’t have a huge amount of hole-punching to do at the end.

One piece of advice I would have at this stage – and I only realised this after starting and having to clear up the mess on my carpet! – is to use a tray or something like that to catch the tiny dots of card removed by the hole punch. This is the result of just part of the hole punching for this first piece:

However, after joining a couple of new strips to my original one I had marked all the dots for the complete piece, and finished punching the holes.

This was the moment of truth – I fed the strip into the musical box and wound the handle . . . and, sure enough, the sound that came out definitely resembled the piece I had written!

*

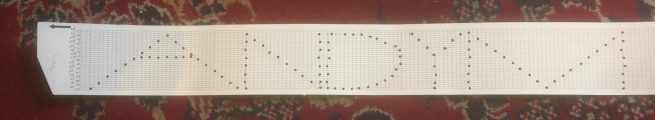

The first experimental piece was pretty straightforward – I punched out my name on a card strip:

Letters of the alphabet are not ideal for this purpose, because they contain a lot of vertical lines (many notes played at once), horizontal lines (the same note repeated many times) and diagonal lines (scales up or down), and not much in the way of tunes; however, this was a reasonable start!

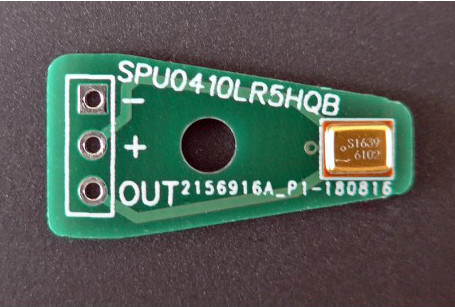

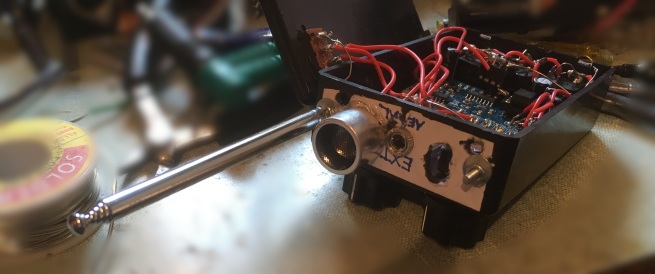

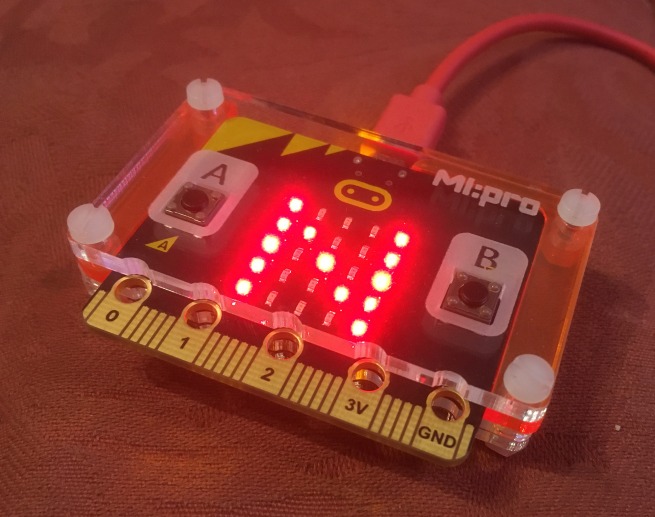

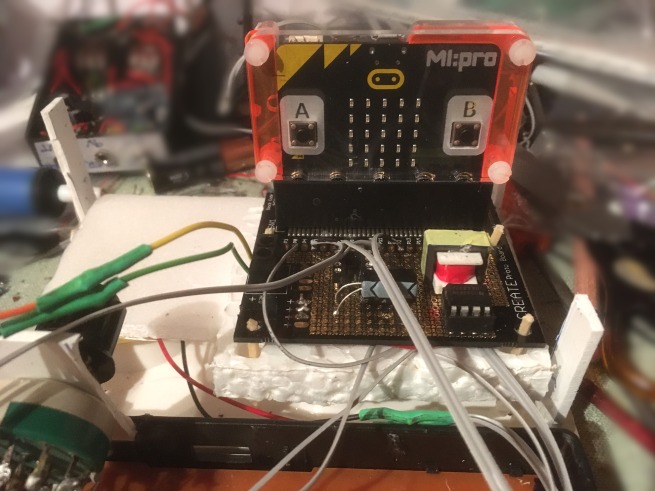

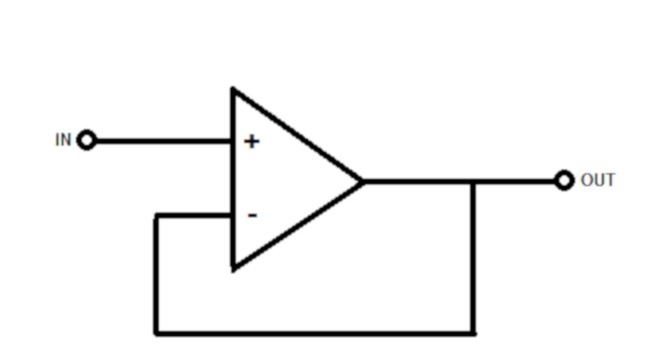

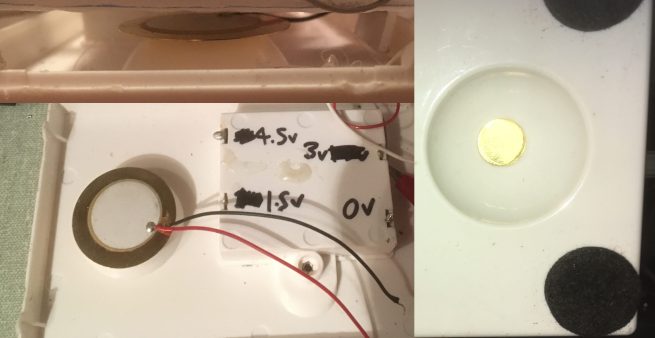

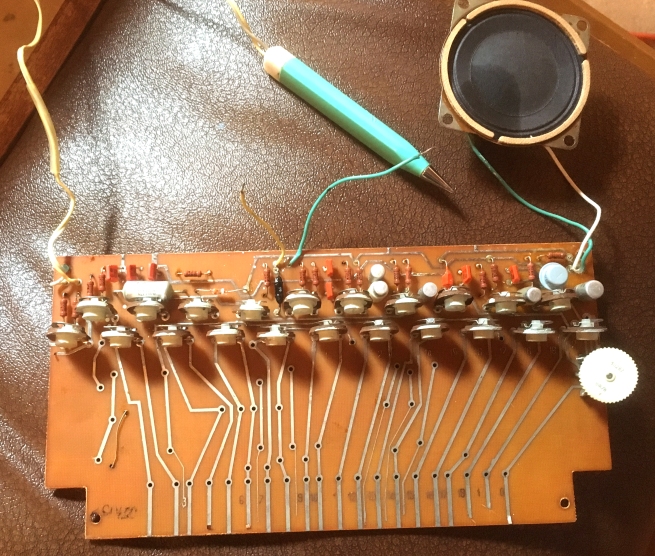

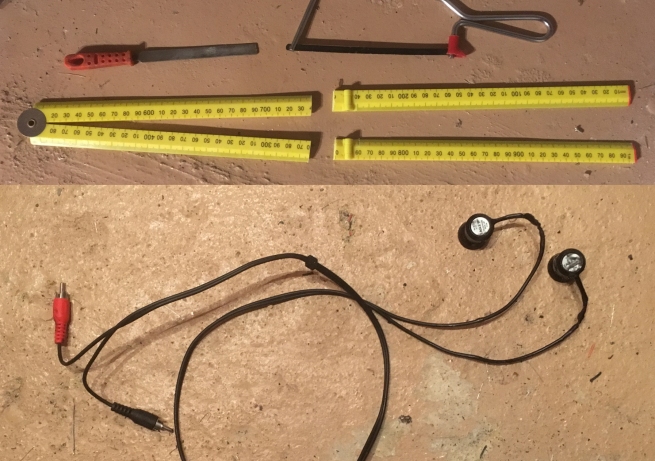

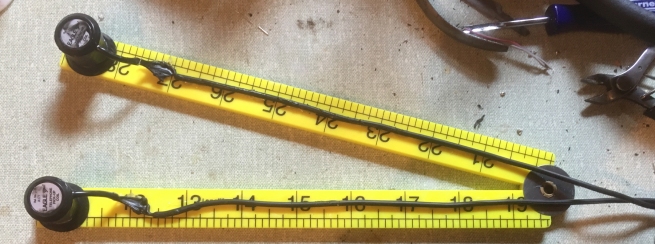

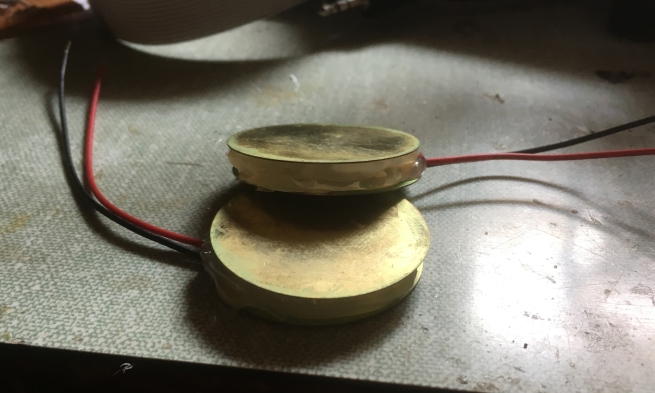

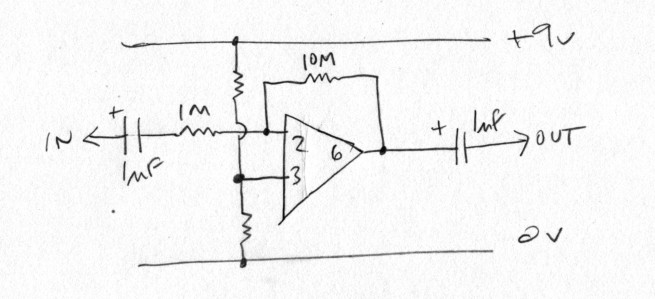

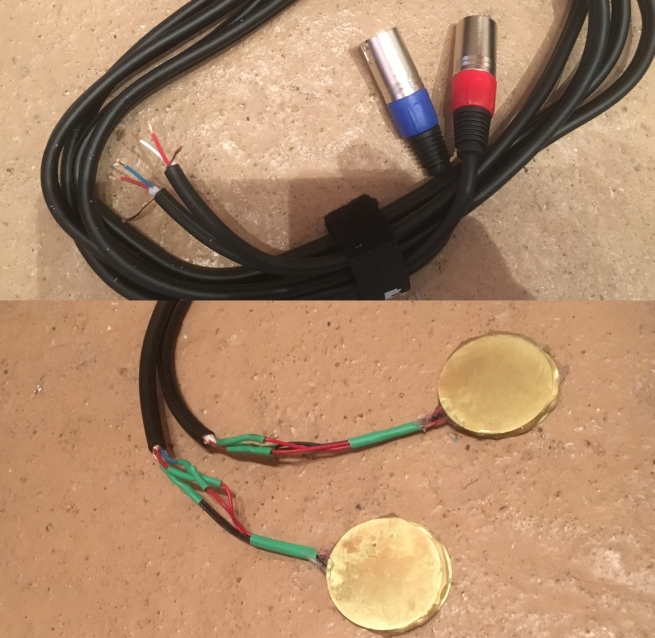

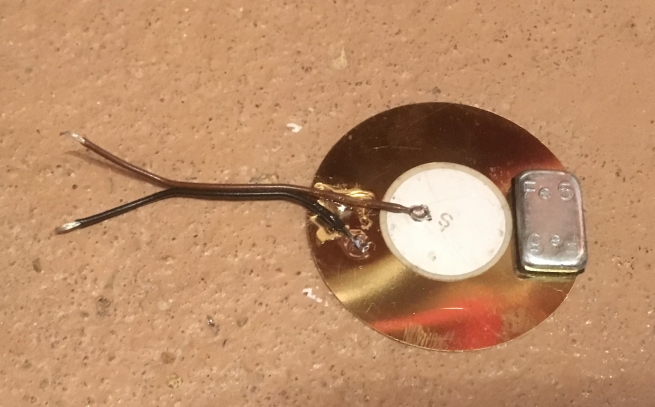

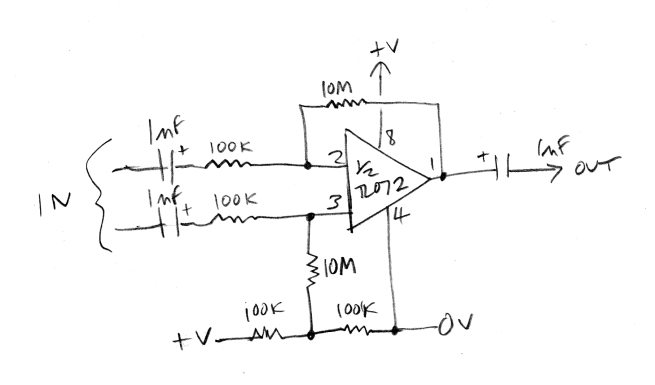

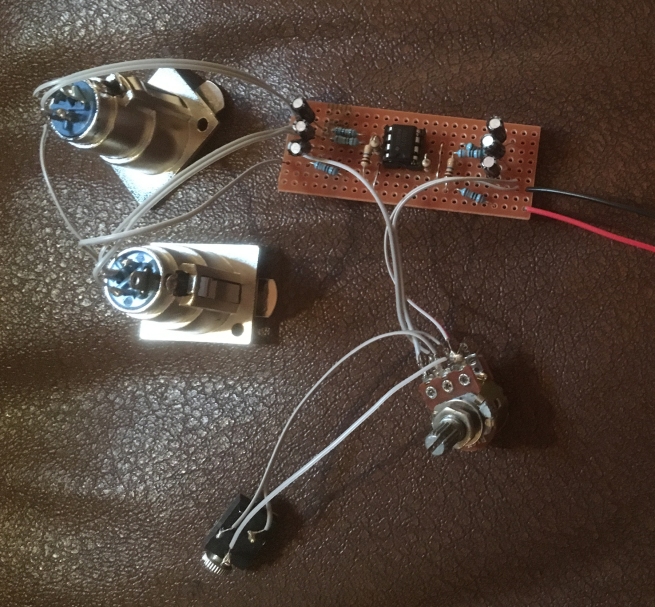

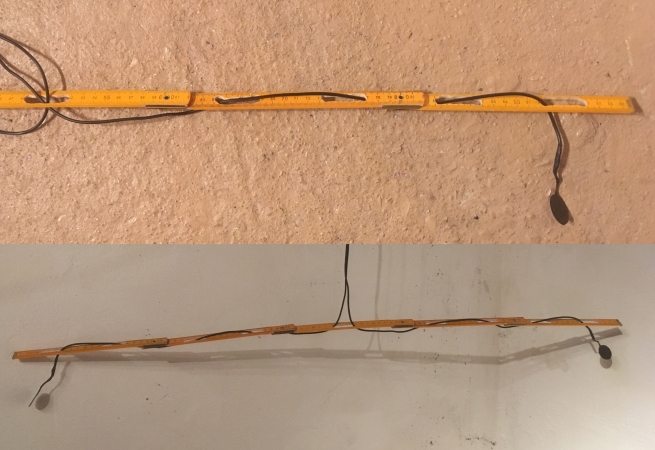

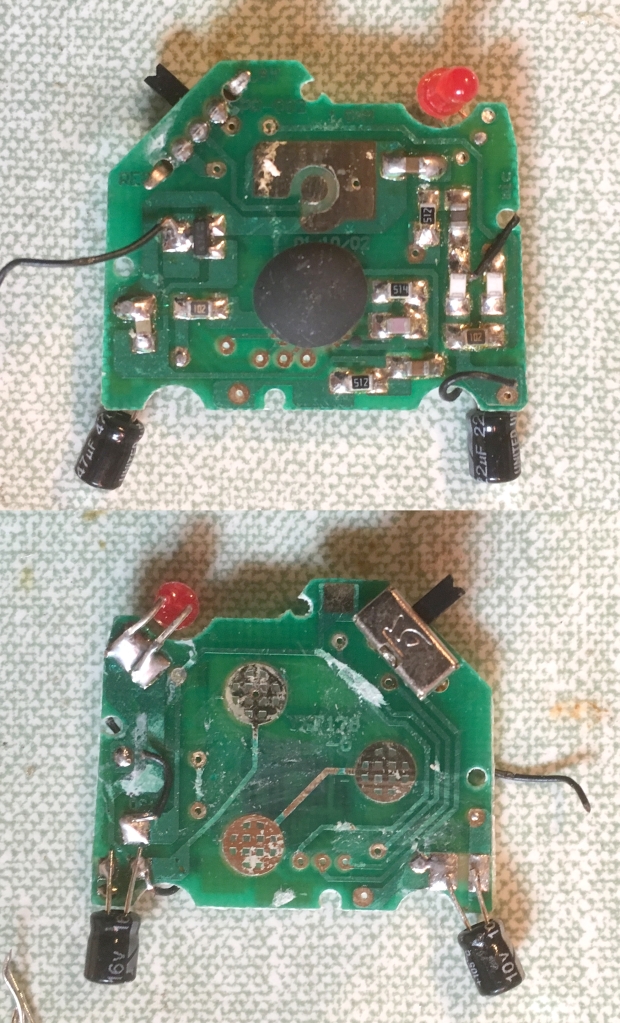

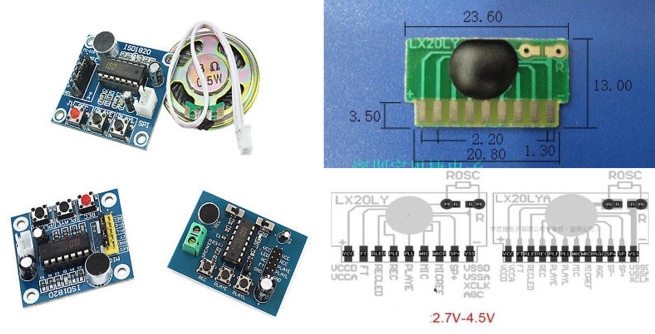

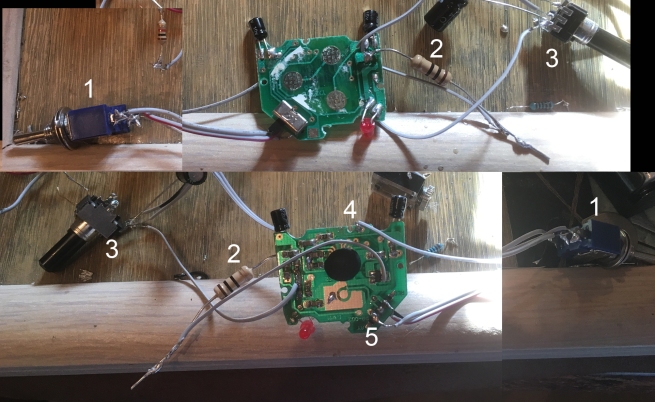

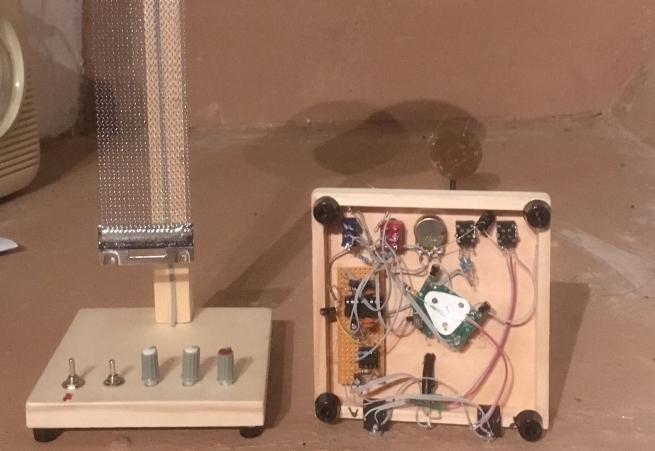

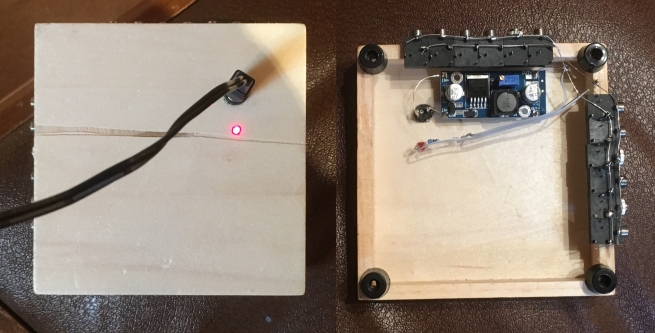

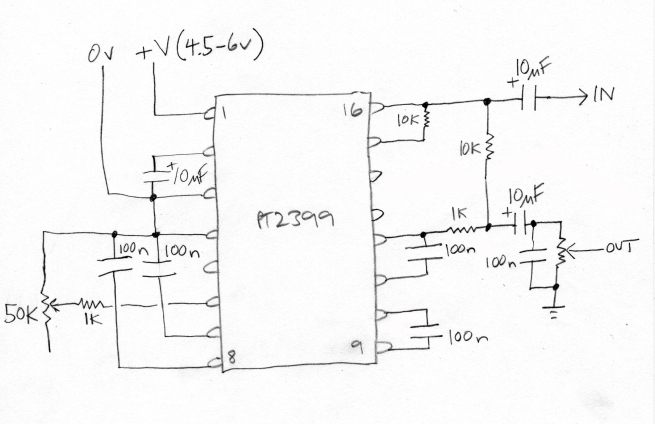

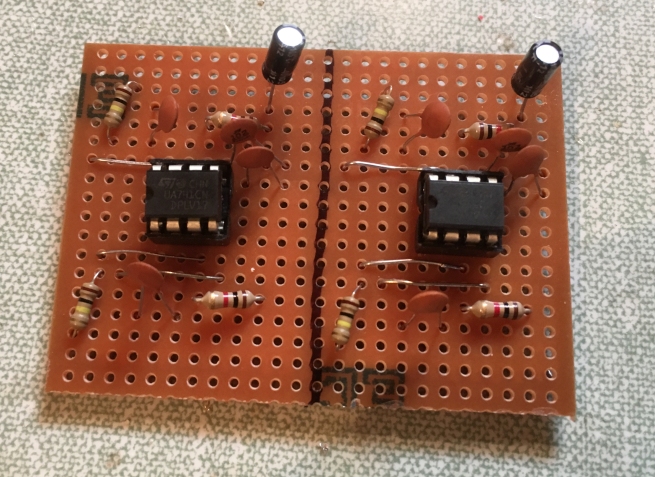

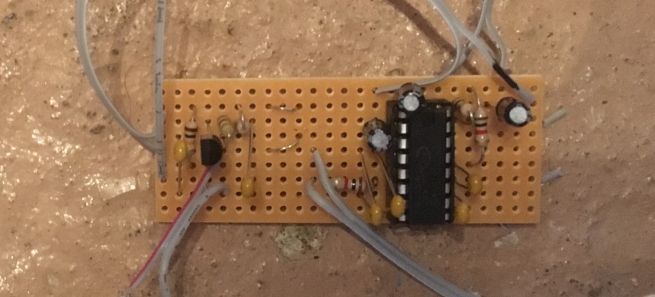

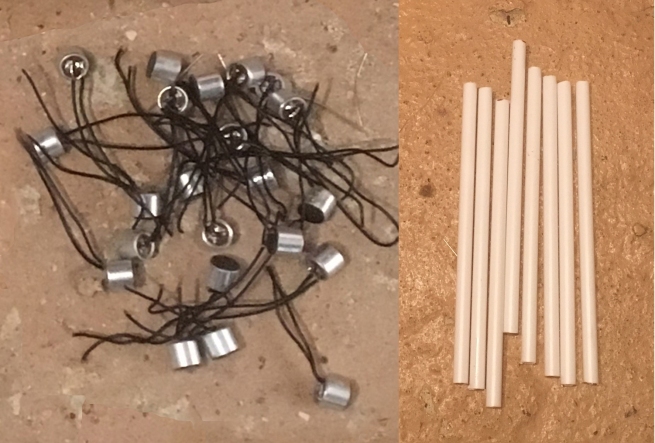

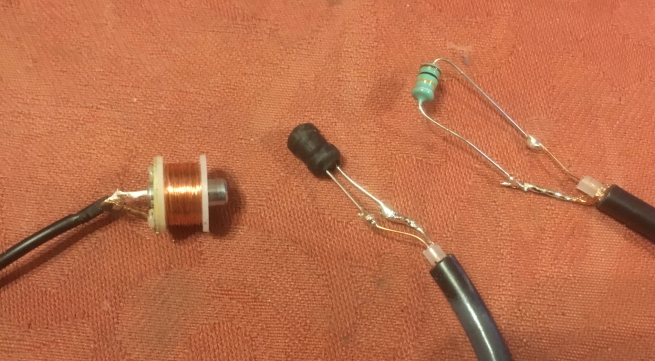

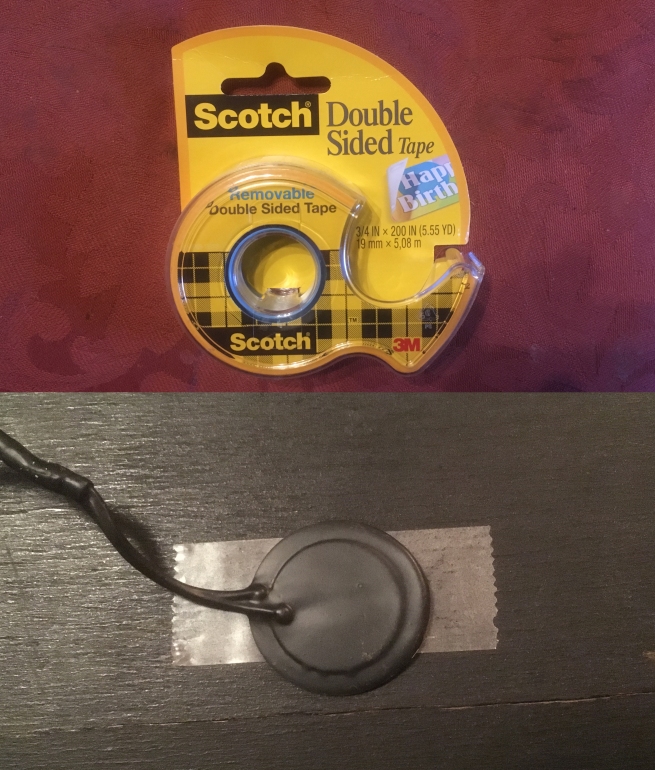

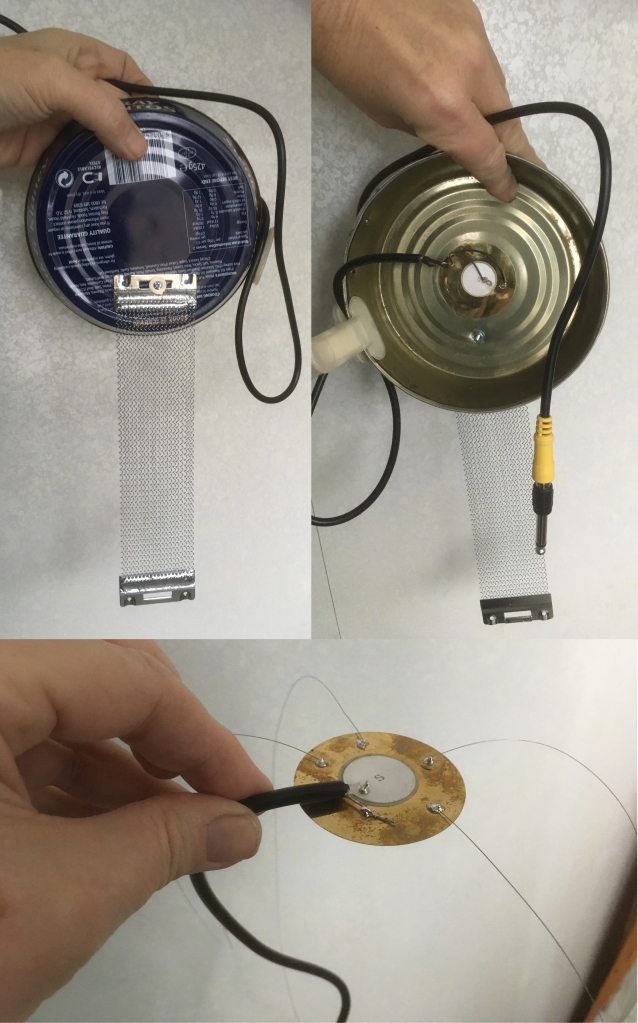

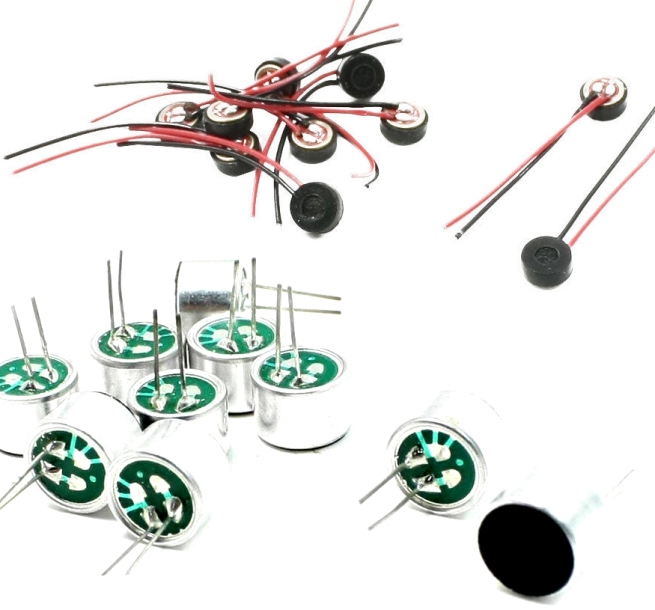

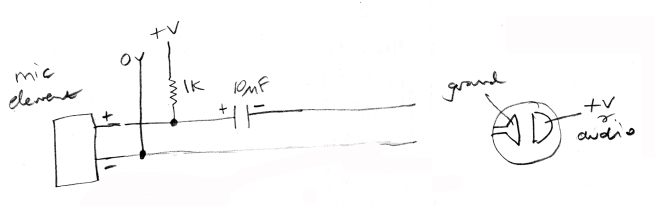

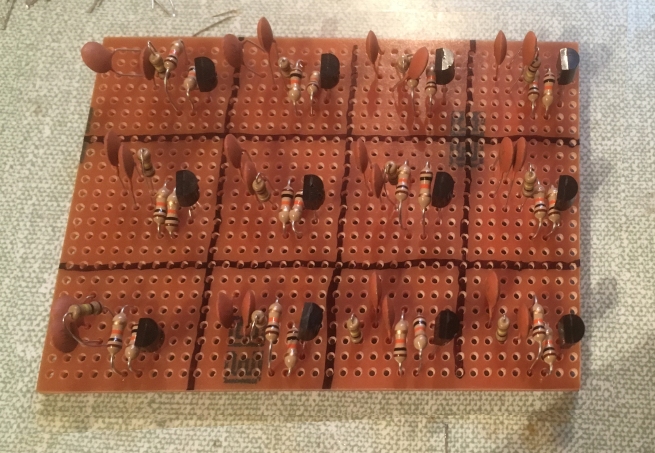

To record the musical box, I used double-sided sticky tape and some piezo contact mics I had made some time ago (as described here).

Here are the two pieces, first the ‘ANDYM’ piece, then the previously composed one (which is called ‘Theme From an Imaginary Spy Film’).

*

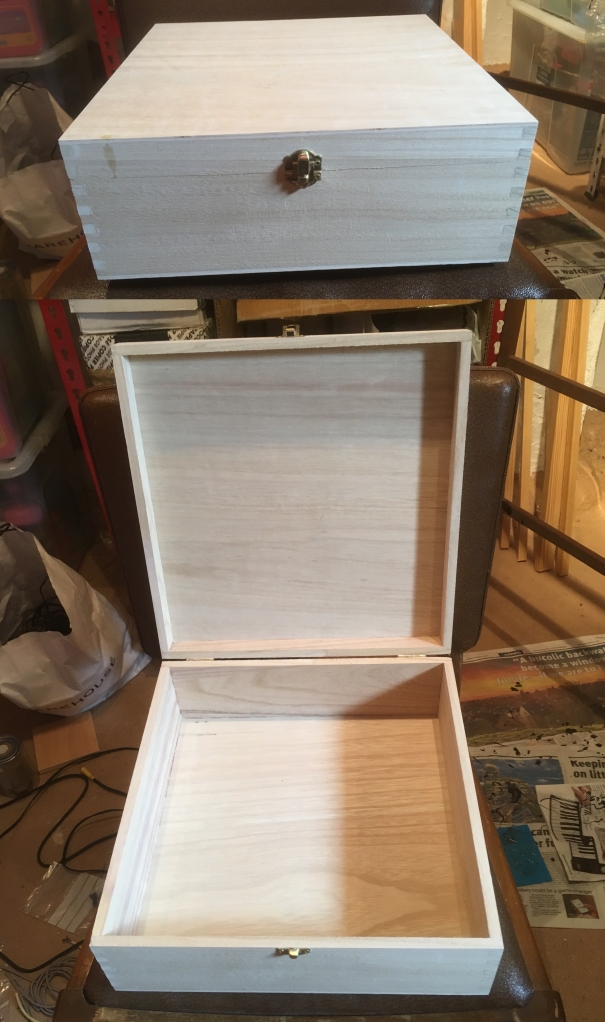

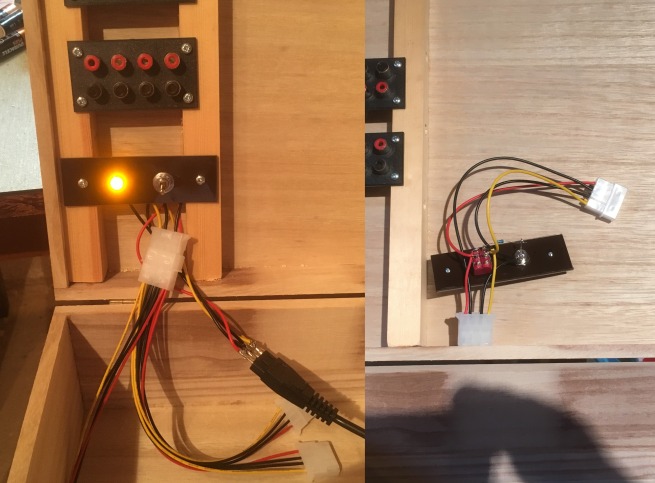

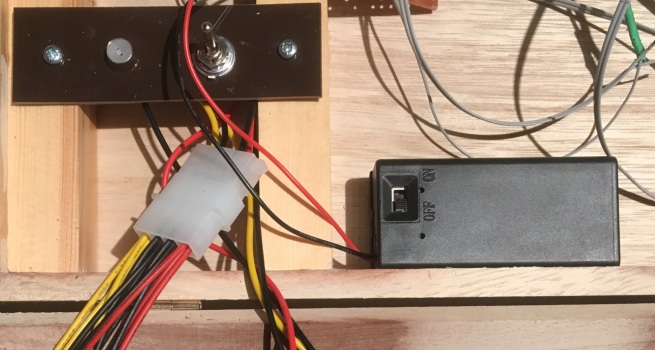

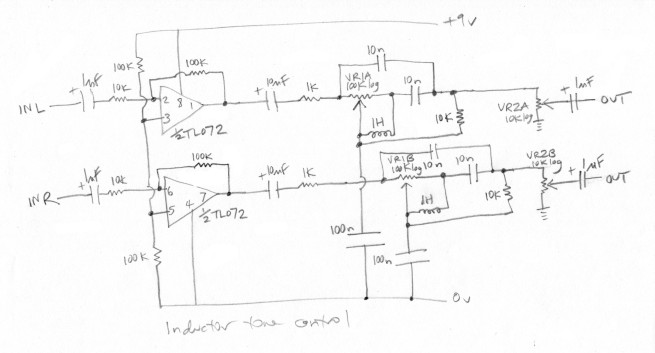

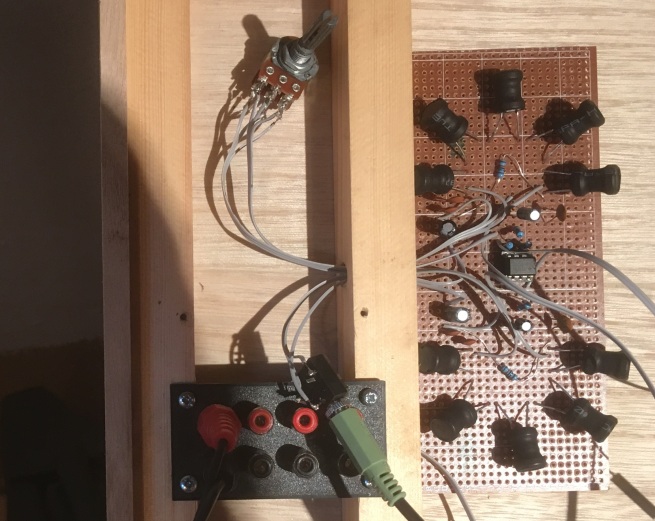

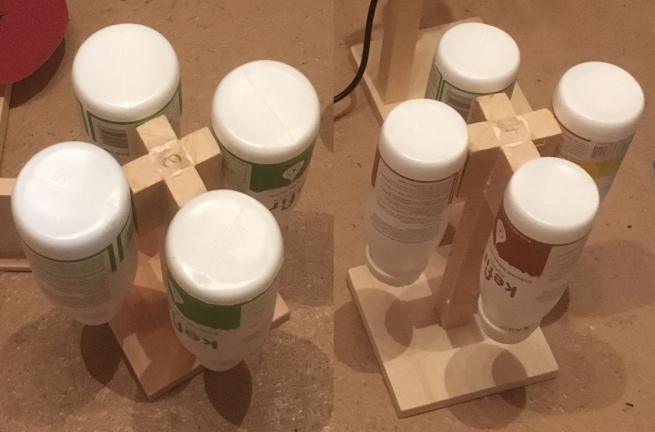

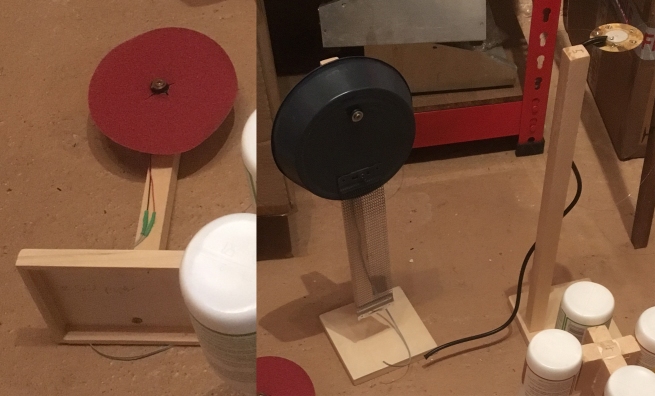

Finally, to keep everything together, I used one of the wooden boxes I originally bought at the time I was making the Inductor instrument. This time, as well as adding the same type of carying handle, I stained it a dark colour and varnished it. It was a very cheap and rather poor-quality varnish, but didn’t look too bad after a quick polish:

and the musical box, the card strips and everything fitted nicely inside: